Technical Specification (all models):

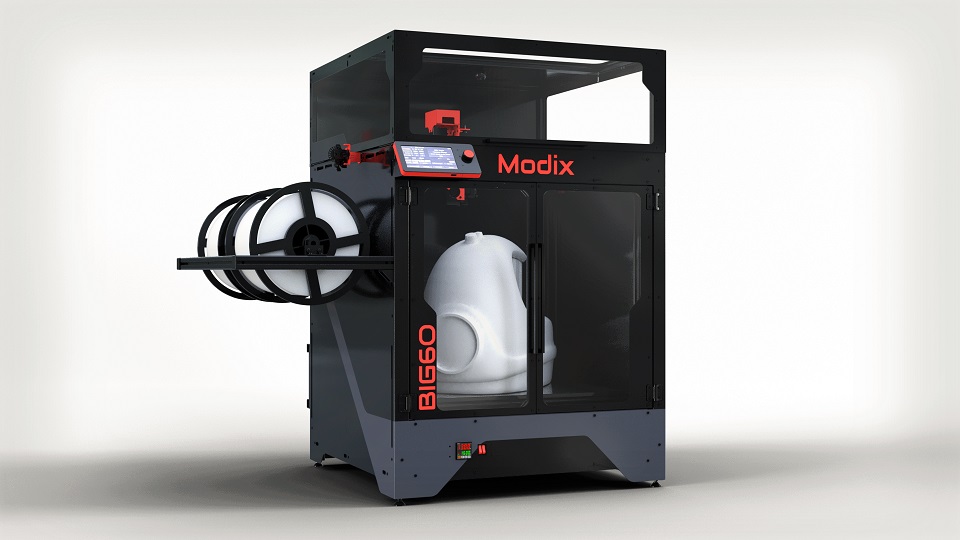

Modix’s Generation 4 lineup represents the latest evolution in large-format 3D printing, delivering enhanced performance and new capabilities. With improved motion accuracy, faster print speeds, and greater reliability, Generation 4 printers enable the production of complex models with internal geometries while reducing post-processing time. Explore the advanced technology that powers Modix’s industry-leading large-format 3D printers.

General Information

- Printing Technology – FFF (Fused Filament Fabrication)

- Delivery – Self assembly kit. Assembly guide includes easy to follow videos and online 3D models that can be rotated and zoomed.

- Unified Core concept- All our printers share the same core design.

- Upgrade – New versions are designed with backward compatibility in mind. Owners of Modix’s printers enjoy upgrades from time to time in both configurations and hardware.

Models Comparison

| BIG-60 | BIG-120X | BIG-120Z | BIG-180X | BIG-METER | EVEREST | |

| Print Volume | 600x600x660 | 1200x600x640 | 600x600x1,200 | 1,800x600x600 | 1,000×1,000×1,000 | 2,000×1,000×1,000 |

| (XYZ) | mm | mm | mm | mm | mm | mm |

| ~23.6×23.6×26 | ~47.2×23.6×25.2 | ~23.6×23.6×47.2 | ~70.8×23.6×23.6 | ~39.7×39.7×39.7 | ~39.7×39.7×39.7 | |

| inch | inch | inch | inch | inch | inch | |

| Machine Size | 906x1060x1,506 | 1,556×1,060×1,506 | 906x1060x2,066 | 2,630×1,060×1,573 | 1,739×1,424×1,976 | 1,356×1,445×3,068 |

| (WxDxH) | mm | mm | mm | mm | mm | mm |

| ~35.6×41.7×53.4 | ~61.2×41.7×59.2 | ~35.6×41.7×75.4 | ~85.4×41.7×62 | ~68.4x56x71.1 | ~68.4x56x71.1 | |

| inch | inch | inch | inch | inch | inch | |

| Shipping Weight | 120 KG | 170 KG | 140 KG | 210 KG | 200 KG | 300 KG |

| ~265 lbs | ~325 Ibs | ~265 Ibs | ~465 Ibs | ~440 Ibs | ~440 Ibs | |

| Enclosure | Optional | Optional | Optional | Included | Included | Included |

| IDEX | Optional | Optional | Optional | Optional | Optional | Optional |

| Z Axis Guides | Hiwin Rails | Hiwin Rails | Included | Included | Included | Included |

| Optional | Optional | |||||

| DUEX | Included | Included | Included | Included | Included | Included |

| Expansion board | ||||||

| Tilt screen & | Optional | Optional | Included | Optional | Included | Included |

| emergency button | ||||||

| Casters | Optional | Optional | Optional | Included | Included | Included |

| Base Price | 5,400 USD | 8,000 USD | 8,000 USD | 17,000 USD | 15,000 USD | 27,000 USD |

| Packing lists: | Big-60 | Big-120X | Big-120Z | Big-180X | Big-Meter | EVEREST |

Chassis & Enclosure

- Solid 40X40 T-slot aluminum profiles

- Powder coated laser cut aluminum brackets and joints

- Enclosure – Closed enclosure made of 3mm black Aluminum Composite Panels (ACP). Enclosure is an optional add-on for BIG-60, BIG-120X & BIG-120Z and a default option for BIG-Meter and BIG-180X.

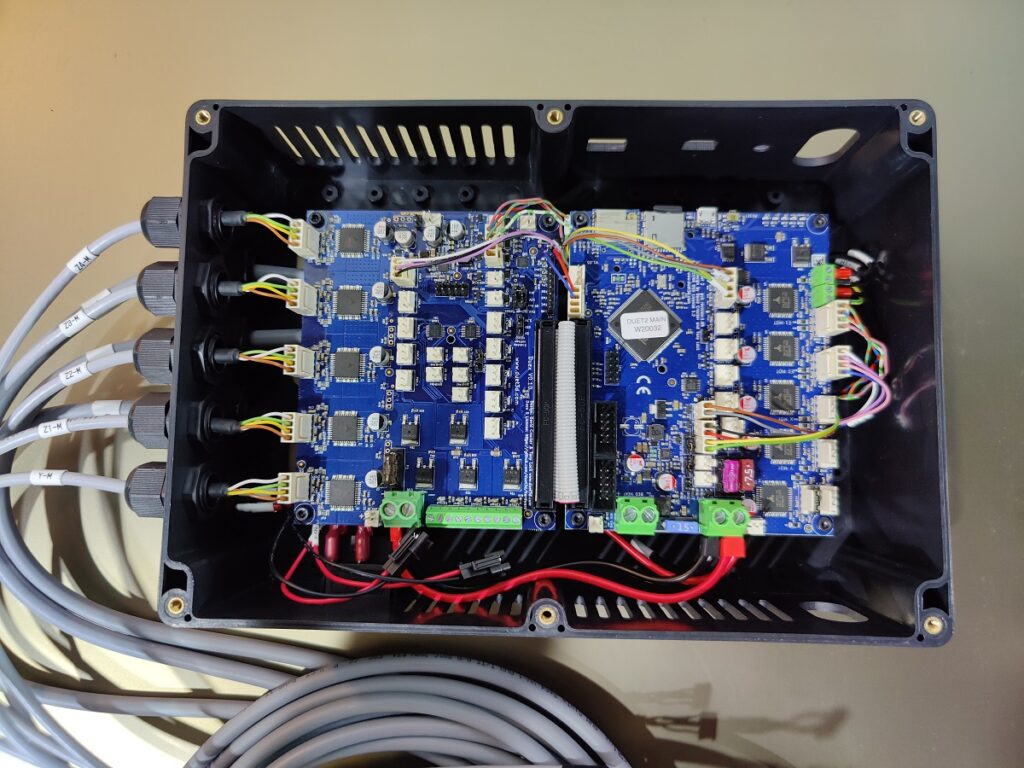

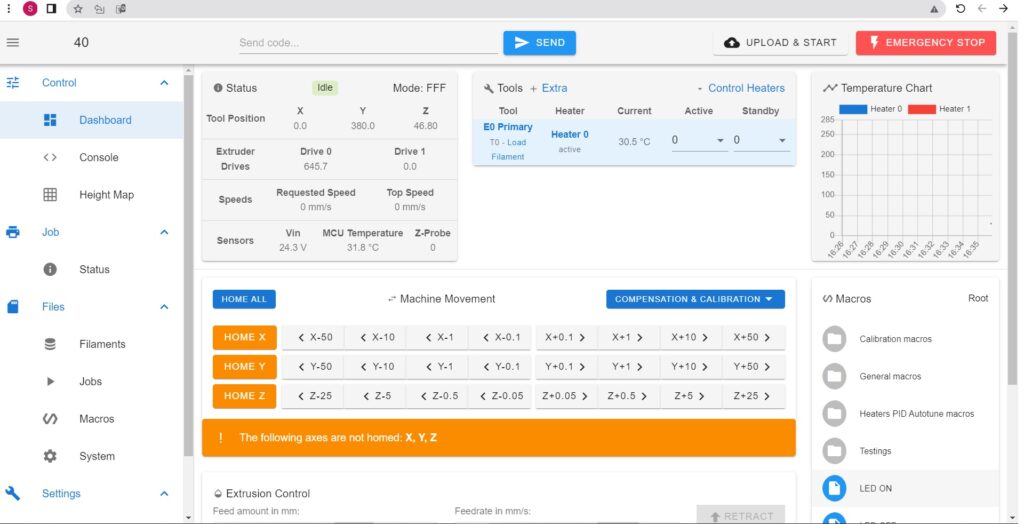

Electronic Controller

Duet 2 WiFi, a powerful 3D Printer controller made in the UK. Duet is a well known and widely supported electronic platform for professional 3D printers. It is made by a respectful company and it is a major factor in our ability to provide ongoing high level of quality and reliability.

- Powerful 32 Bit Processor

- Dedicated WiFi module with external antenna

- Quiet TMC2660 stepper drivers, up to 256 micro-stepping.

- High speed uSD card and support for a second external SD card if required.

- Dual extruders controlled on the main board, up to 5 additional stepper motor drivers are controlled on the DUEX expansion board.

- High Power rating: Each stepper driver is capable of 2.8A motor current, currently limited in software to 2.4A.

- Access the printer via a PC, tablet or smartphone on a local network.

- Set up and control your printer through the web interface.

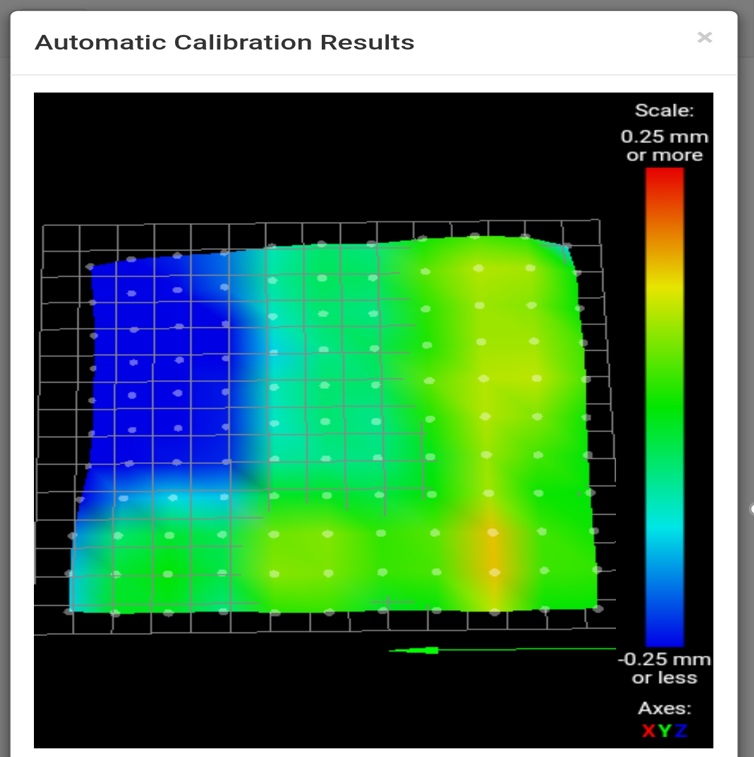

Fully Automated Calibration

All our printers’ models are delivered with the electronic expansion board named Duex. This allows allocating a dedicated driver per each motor for both Z axis and X axis. As a result, Modix is now offering a full set of automated calibrations routines including:

- Bed tilting calibration

- Bed leveling

- Gantry alignment

- Z offset calibration

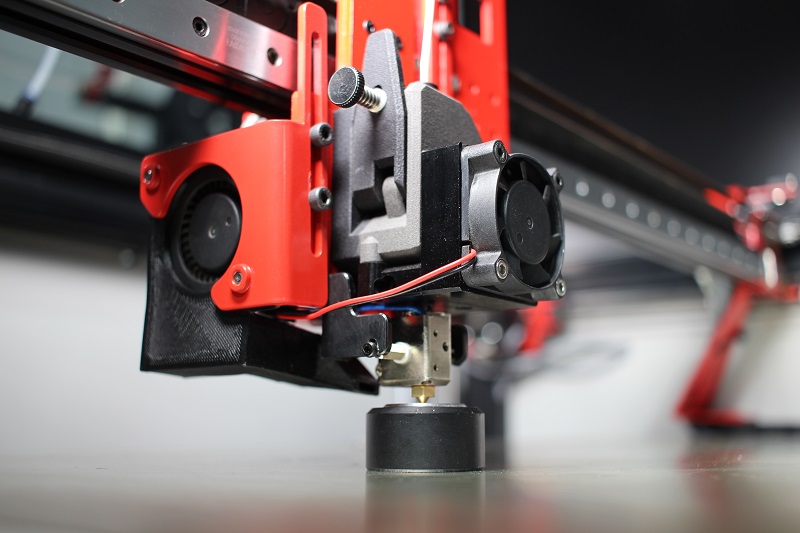

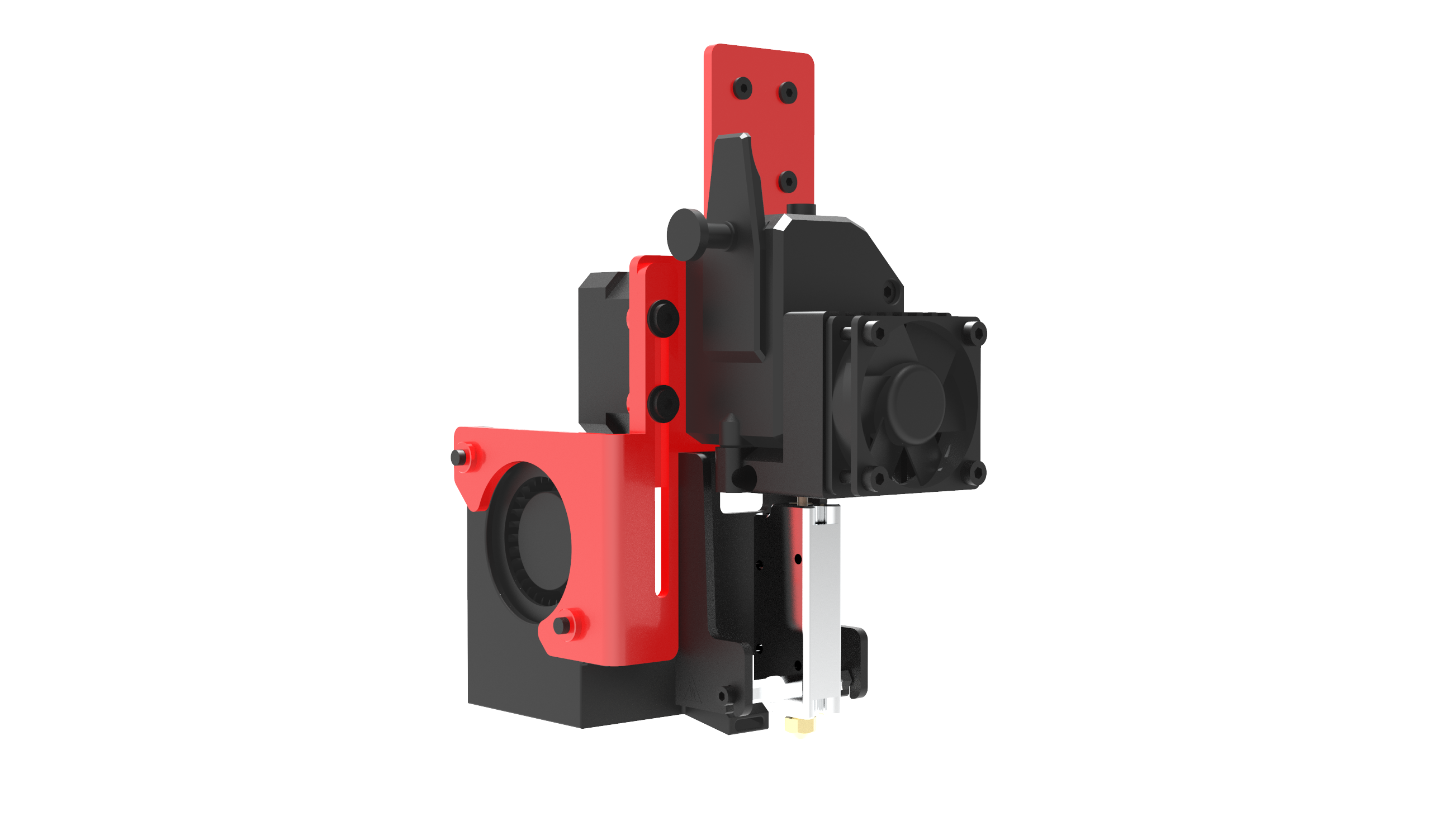

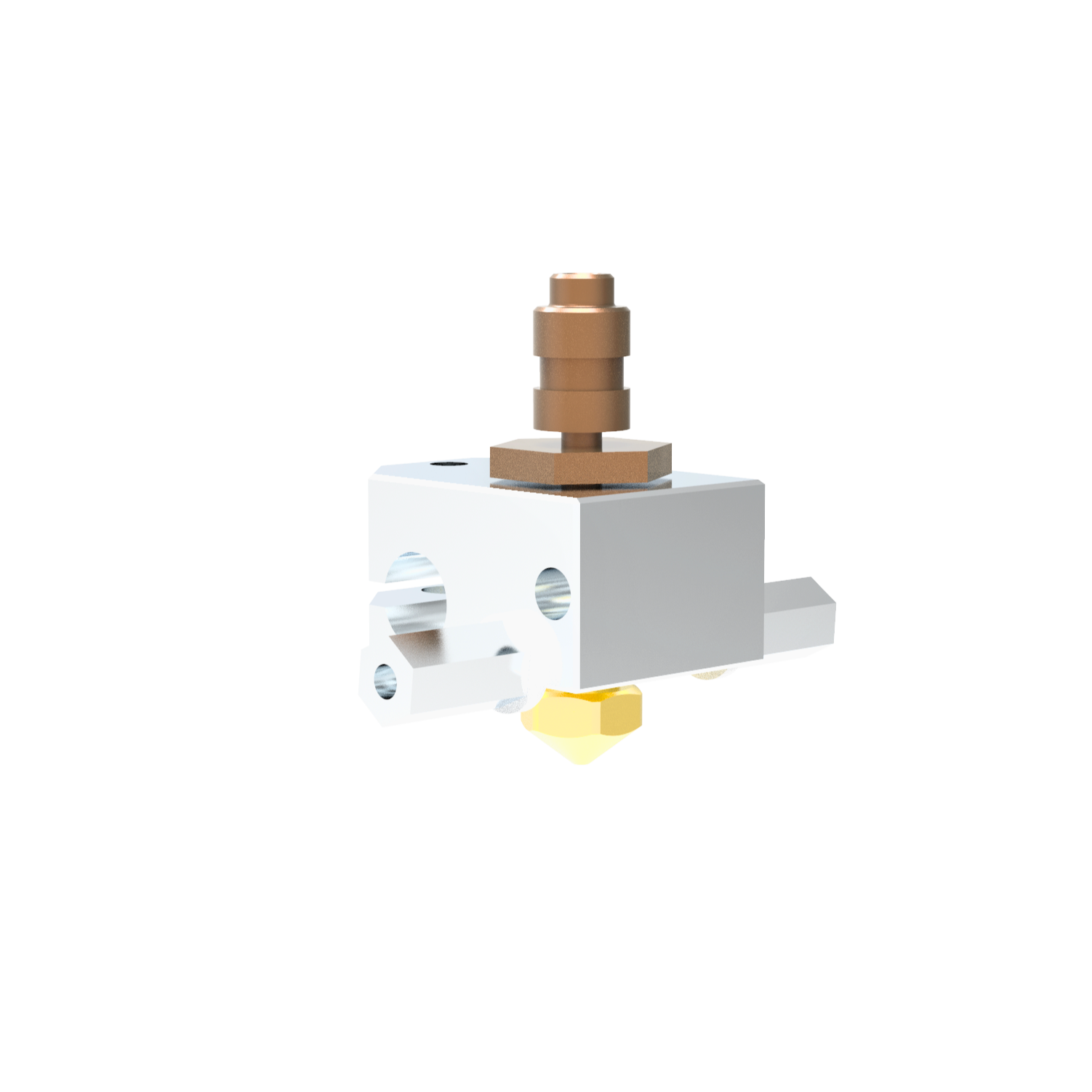

Griffin Print Head

The Griffin print head family consists of 4 distinct configurations, all built on a shared design concept. Each print head is tailored to a specific printing profile and use case, providing users with the flexibility to optimize their workflow. Modix’s strength is its versatile offering, ensuring seamless adaptation to both current and future needs.

- Griffin (Standard) – The default option, offering a balanced combination of speed and detail.

- Griffin High-Resolution – A shorter hotend designed for ultra-precise prints with fine details.

- Griffin High-Flow – A double-length hotend for significantly faster extrusion and reduced print times.

- Griffin Ultra – A complete extruder system with an extended hotend, transforming multi-day prints into hours.

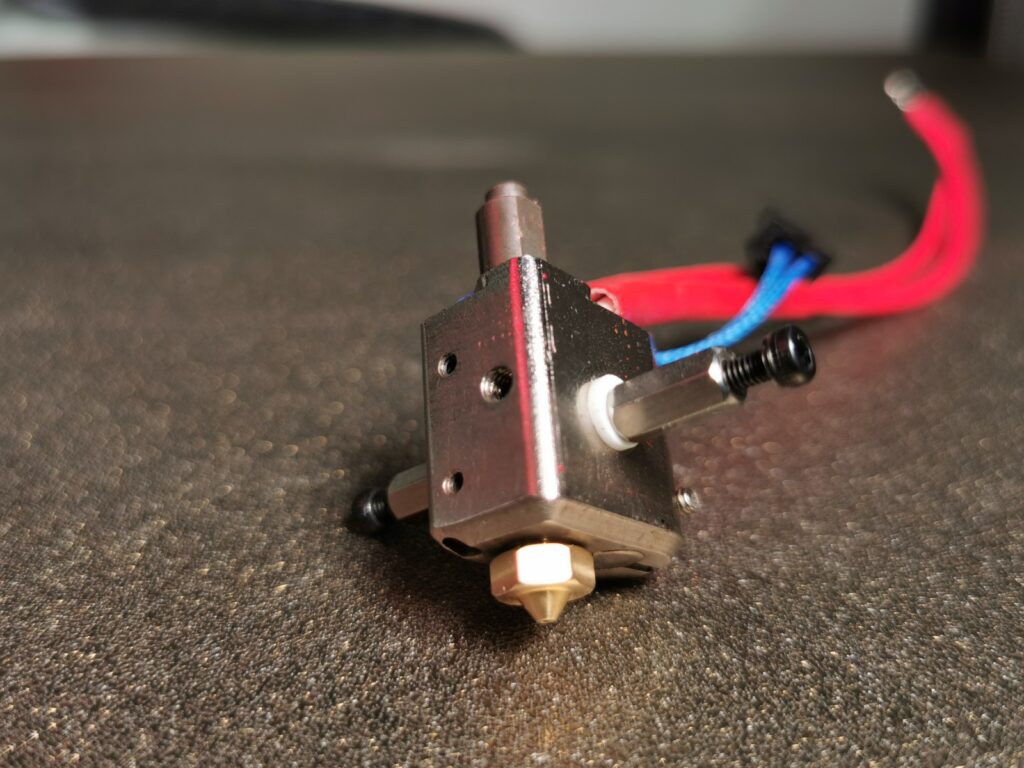

The Griffin eco-system design:

Performance: The Bondtech extruder features a dual drive-gear system that grips the filament from both sides, ensuring consistent and reliable feeding. The heat block, made of nickel-coated copper, enhances heat transfer and supports high-temperature printing. Additionally, an upgraded PT-1000 temperature sensor allows for printing at temperatures up to 500°C. While the hotend components are rated for 500°C, they have been successfully tested up to 340°C.

Reliability: Large-scale 3D printing often carries the risk of the print head scratching or colliding with thick-layer models, potentially bending or breaking the heat break. The new print head features a rigidly mounted heat block, enhancing reliability and significantly reducing these risks.

Easy Swap: The mounting bracket design enables users to effortlessly swap the entire filament melting subsystem. This allows for dedicated setups tailored to specific filament types—for example, maintaining one setup for abrasive carbon-filled filament and another for PLA prototyping.

Compact Design: The new design maintains the previous design benefits of compact design that preserves the generous Z-axis travel and is compatible with the vast offering of E3D Volcano nozzles coming in numerous sizes and materials.

Automatic Z off-set calibration: The new print-head allows automatic Z off-set calibration between the nozzle and the BL Touch probe. This is easier and more precise than the manual procedure.

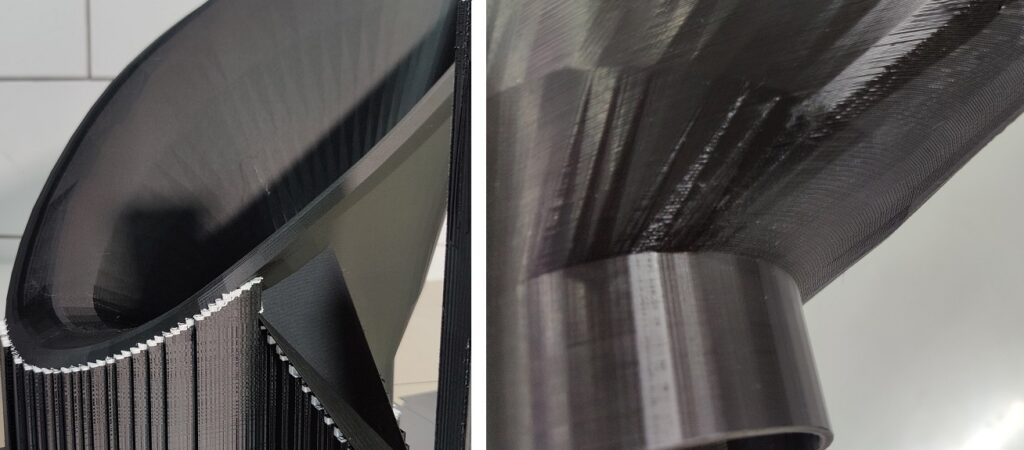

Griffin High-Flow Hotend

Griffin High-Flow Hotend is an optional add-on designed for customers who print large bulky objects and need to print fast. It is also an excellent choice for printing thick vase mode style objects since the single walled objects are stronger.

This add-on is provided with 80W heater and a thermistor. The new addition is now delivered with a mounting CNC made bracket. This mounting protects and stabilizes the long heatblock during printing. As a result it provides high print quality as vibrations are minimized during accelerations.

Includes:

Griffin HF Heat-block, 80W heater, PT-1000 Thermistor & 1mm nozzle.

Griffin Ultra

The Griffin Ultra is Modix’s most powerful high-flow hotend, extruding over 500 grams per hour with 1.75mm filament. With four times the melt zone of the standard Griffin and dual XXL cooling fans, it slashes print times—what once took 12 hours now finishes in just 2.

- Compatible with Gen4 & Gen3 BIG printers, including Gen4 IDEX.

- Nozzle diameter: 1.6mm (compatible with standard Griffin nozzles).

- Layer height range: 0.3 – 1.2mm.

- Print speed: Up to 250mm/sec (with 0.3mm layers).

- Flow rate: 160mm³/s @ 1.6mm nozzle, 1.2mm layer height.

- Print head weight: 900g (includes motor & BMG).

- No impact on Z-axis; X-axis reduced by 50mm, Y-axis reduced by 50mm in IDEX mode.

A must-have for professionals looking to maximize speed and efficiency.

Griffin High-Resolution Hotend

Designed for precision-focused applications, this hotend is 50% shorter than the standard, allowing for tighter retractions and enhanced accuracy. It is ideal for printing intricate models, fine details, and small parts with high dimensional accuracy.

- Nozzle sizes: 0.2 mm – 0.8 mm

- Max temperature: 340°C

- Flow rate: Up to 15 mm³/s

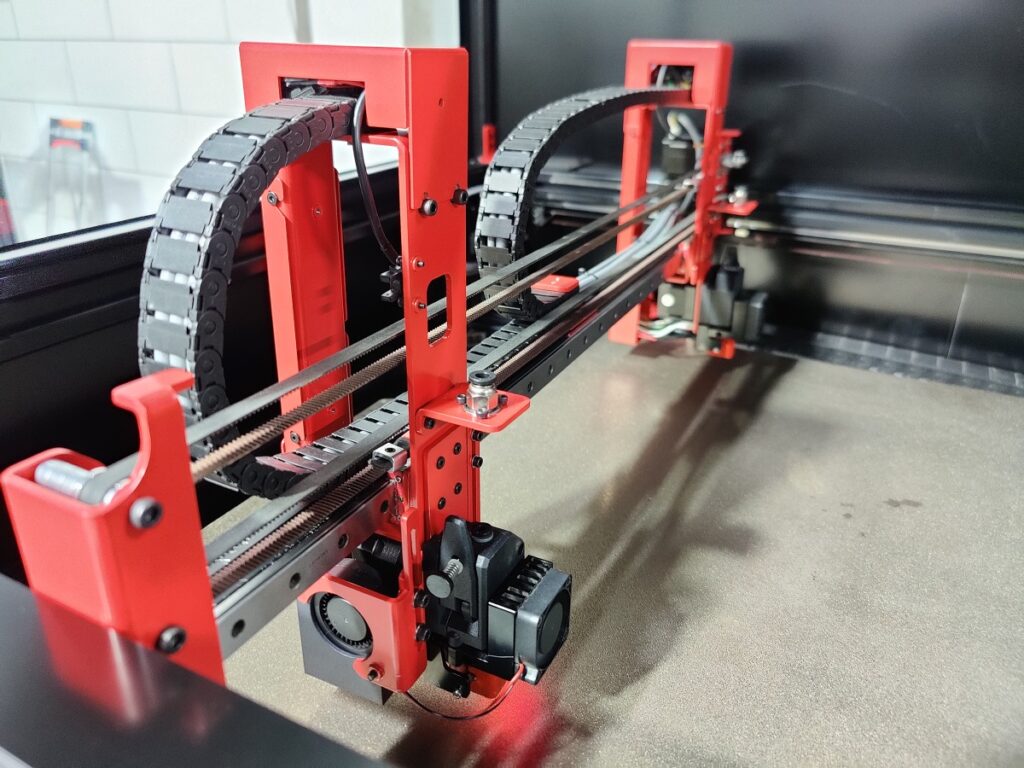

IDEX dual printing add-on

“IDEX” stands for independent dual extruder, where each extruder is capable of moving independently from each other. As a result, while the active extruder is printing, the second extruder is “parked” outside the printing area. Therefore, dual material printing made with IDEX technology comes out cleaner and with higher success ratios in comparison to other configurations as such the two print heads are installed side by side on the same carriage.

IDEX allows printing of advanced models that have internal geometries by using water-soluble filament. In addition, printing the dense support layers (interface layers between the model and the solid support structure) with a breakaway support filament, saves a lot of manual labor for support removal. In addition, since there is no need to keep air gap between the dense support and the model itself as normally happened when using the same material for support, the supported bottom surface of the models comes out clean and smooth. This saves a lot of time needed usually for sanding during the post process.

The IDEX is sold as an optional add-on for all generation 4 printers. includes:

- Secondary printing subsystem: Griffin print head, clog detector, PTFE, spool mount.

- Motion system: secondary Y axis motor with the required components (belts, pulleys etc.).

- Metal brackets for both Y axis and print heads

- Wires, drag chains and optical end-stops.

Automatic Filament Changer

Modix’s IDEX can also be used as an automatic filament changer. When using the same filament on both print heads, the printer will be able to switch between the print heads automatically once one the printer detects a filament run-out.

Here are the benefits:

Get prints faster – One of the biggest challenges of 3D printing is the need to constantly monitor and maintain the printer. This can be especially frustrating when the machine has to sit idle overnight while waiting to be fed with a new filament spool. That’s where the Modix IDEX Filament Changer comes in. This clever technology allows the printer to switch out filament spools on its own, without having to pause its operation and wait. That means you can keep your printer running around the clock, without losing time on waiting for someone to service it.

Improved print quality – Not only does the Modix IDEX Filament Changer save you time, but it also helps to improve the quality of your prints. By not having to open the enclosure for service, the printer is able to maintain its chamber’s temperature, preventing the partly printed model from shrinking. This allows you to produce higher quality prints with fewer defects. If you want to take your 3D printing to the next level, be sure to check out the Modix IDEX add-on.

Demonstration of the automatic

filament changer

Tilt Screen & Emergency Button & Frontal Power switch

This trio feature combo is available as standard for BIG-Meter and BIG-120Z and offered as an add-on for the rest of the printers.

Tilt Screen – Mounted on an articulated arm, the tilt screen is a convenience feature. It is very useful during print head calibration process and other maintenance routines as you can always turn the face towards you. Left right, upwards or downwards.

Emergency Reset Button – Together with the tilt screen update, an emergency reset (software reset) button is now located on the front of the machine. This control and safety feature will allow you to immediately stop prints whenever needed.

Frontal Power Switch –easy to reach power on/off button. Useful when the printer is installed in a tight corner.

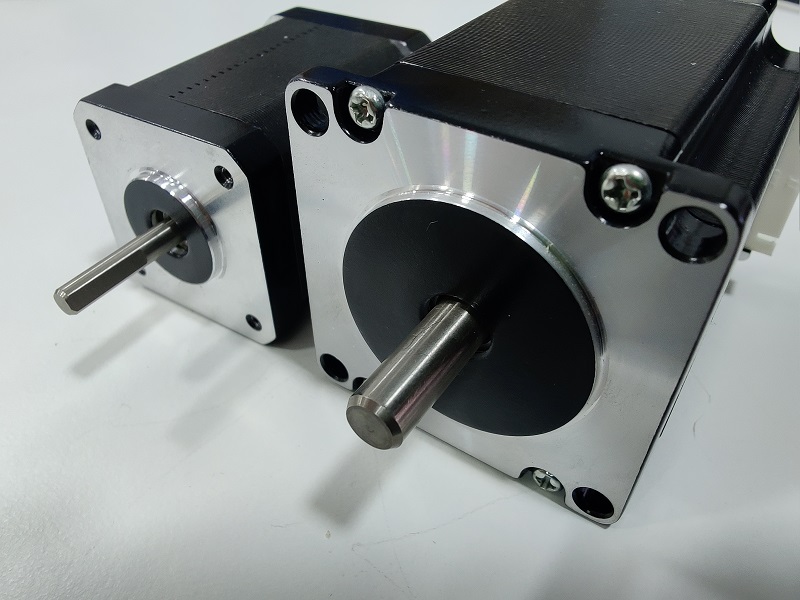

Motion System

- HIWIN MGW9H linear guide rails

- Four Z ball screws for Z axis movement. 12mm diameter, 4mm pitch

- 9 mm width Gates GT2 timing belt, reinforced with fiberglass

- Motors: X & Z Axis: NEMA-23, Y Axis: NEMA-17

Mechanical position accuracy: X-10 Micron, Y-10 Micron, Z-0.5 Micron - Print speed (based on 0.4mm nozzle):

Up to 100 mm/sec – normal quality

Up to 250 mm/sec – draft / non functional infill

Up to 350 mm/sec – travel

Larger nozzles normally are required to print slower but provide parts much faster due to a reduced number of layers.

Power

- Support both 110V and 230V

- For electronics: Meanwell 24V 280W Power Supply

- Protections: Short / Over-load / Over-voltage / Over-heating.

- No load power consumption<0.5W

- LED indicator for power on

- Aviation grade switches and connectors

- Heat Bed AC powered heater 1370 Watt

- PID bed heater controller by Autonic

- BIG METER and 180x require 208-240V, 32A connections

- North America customers: NEMA L6 30P 30A outlet

- EU/AU/UK customers: IEC 309 32A Blue (2P+E) outlet

- Tripp Lite PDU for meter and 180x

- North American customers: https://www.tripplite.com/support/PDUH30HV

- EU/AU/UK customers: https://www.tripplite.com/support/PDUH32HV

Print Bed

- 6.35mm thick, Alcoa Mic6 milled cast aluminum plate, made in the USA.

- AC powered bed heater 1370 Watt (1,200 Watt for 110V users). Requires a dedicated independent 15A AC source.

- Dual heating zones. Inner 200X200mm size for small objects and lower power consumption.

- Max temperature – 110oc (with enclosure)

- Print surface – PEI film with 3M high temp adhesive sheet.

Removable Magnetic Bed

This add-on will greatly improve the user experience and save you time on a daily basis. Modix’s printers are delivered by default with a PEI sheet that releases the print once the bed is cooled down to room temperature. With the removable magnetic bed add-on, users do not need to wait or work hard with a spatula and can easily and immediately remove objects after completing the print job by simply bending the spring steel plate.

This add-on includes an adhesive magnetic sheet that should be fixed to the aluminum bed plate and a removable spring steel plate that should be placed on top of it.

The flexible spring steel plate can be printed on from both sides. One side is PEI powder coated providing textured bottom surface and the other side is serviced with a smooth PEI sheet providing a glossy bottom finish.

Another advantage is with maintenance, the PEI installed on the bed plate can degrade over time. Print removal with a spatula may result in unwanted scratches that later appear at the bottom of the printed object. Replacing the PEI on the removable spring steel or even buying a spare unit is much easier than removing it from the bed plate itself.

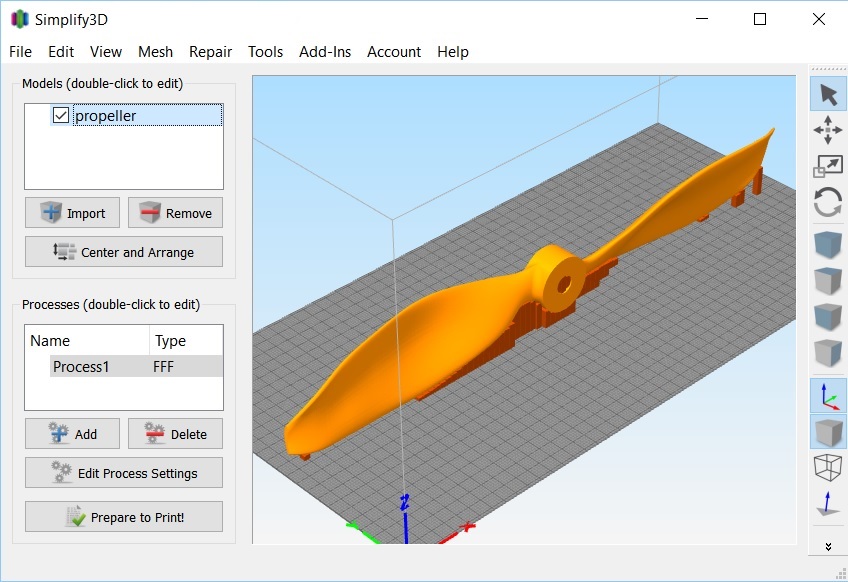

Software

- Open-source Duet RepRap firmware. The leading firmware for 3D printing allowing numerous configurations and easy customization using the macro system.

- One can choose from any available slicer and 3D printer controller including: Slic3r, Cura, and Simplify3d. Specific printer configurations are supplied in the customer zone.

Clog Detector

Previously an optional add-on and now default with every printer, is an improvement to the printer’s reliability. The clog detector is provided with a custom highly sensitive encoder capable of detecting for following potential failures:

- Hot-end clogs

- Knots in the filament spools

- Filament run-out

- Under extrusion such as when the nozzle temperature is too low, or the nozzle is too close to the bed.

When a failure is being detected, the printer is paused and the print job can be saved. No more discovering your printer printing midair!

This add-on is provided as a drop-in replacement for the current filament run-out sensor. Consider purchasing two units for dual print head configuration.

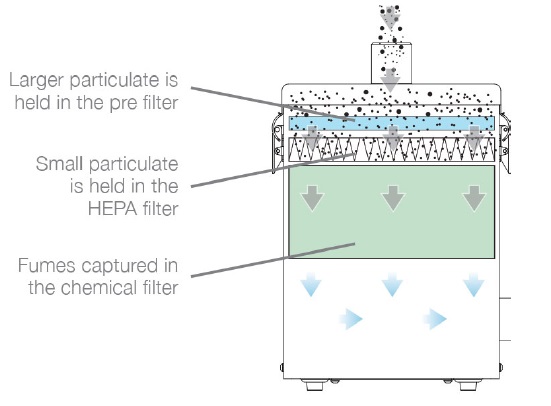

Active Air Filter

The Modix Active Air Filter (MAAF) is an external air filter device. The filter cleanses the printers’ chamber by capturing micro-particles and gas fumes that are released from melted filament throughout the 3D printing process. MAAF provides a constant air cleansing process during the entire printing process, circulating the air in and out and back into the printer while cleaning it repeatedly.

Multi-layer filtering

A large fan inside the device draws the air from the printer through a flexible vent tube connected to the top of the device. The air is then guided through a set of three filters before it is circulated back into the printer.

The triple filter system includes

1. Pre-Filter – Remove large dust particles from the air.

2. HEPA Filter – High-Efficiency Particulate Absorbing (HEPA) filter, composed of a mat of randomly arranged fiberglass fibers designed to capture tiny particles released during printing.

3. Active Carbon Filter – Clean the air from toxic fumes released during the 3D printing process.

It is about your health!

Sub-micron particles and fumes released during the plastic melting process pose risk to your health. Therefore, every owner of a Modix 3D printer is strongly advised to install an air filter. Air filter is a MUST-HAVE add-on if you intend to print with any plastic beyond PLA, i.e. PETG, ABS… Although common knowledge is that printing PLA in a well-ventilated room is fine, there is no clear definition of proper room ventilation and during the winter and summer times windows are normally closed.

Controlling the air speed

Frontal speed selector allows controlling the air flow speed. Running the filter on the lowest speed during the printing process will not affect the internal chamber temperature while providing effective filtering. By the end of the printing, you can set the speed for the highest option for a few minutes in order to ensure the complete chamber has been cleaned of any harmful additives opening the doors.

Spare Filters

Considering the daily use of the printer in a clean room, the HEPA/Carbon combo filters last from 6 to12 months and the pre-filter from 3 to 6 months. An alert indicator to change the is located on the front panel.

Crash Detector

Previously an optional add-on and now default with every printer is an additional layer of safety in rare cases where the BL-Touch bed leveling probe fails and this failure is not being detected by the printer controller. In this case, the detector will prevent the print head from crashing into the bed plate.

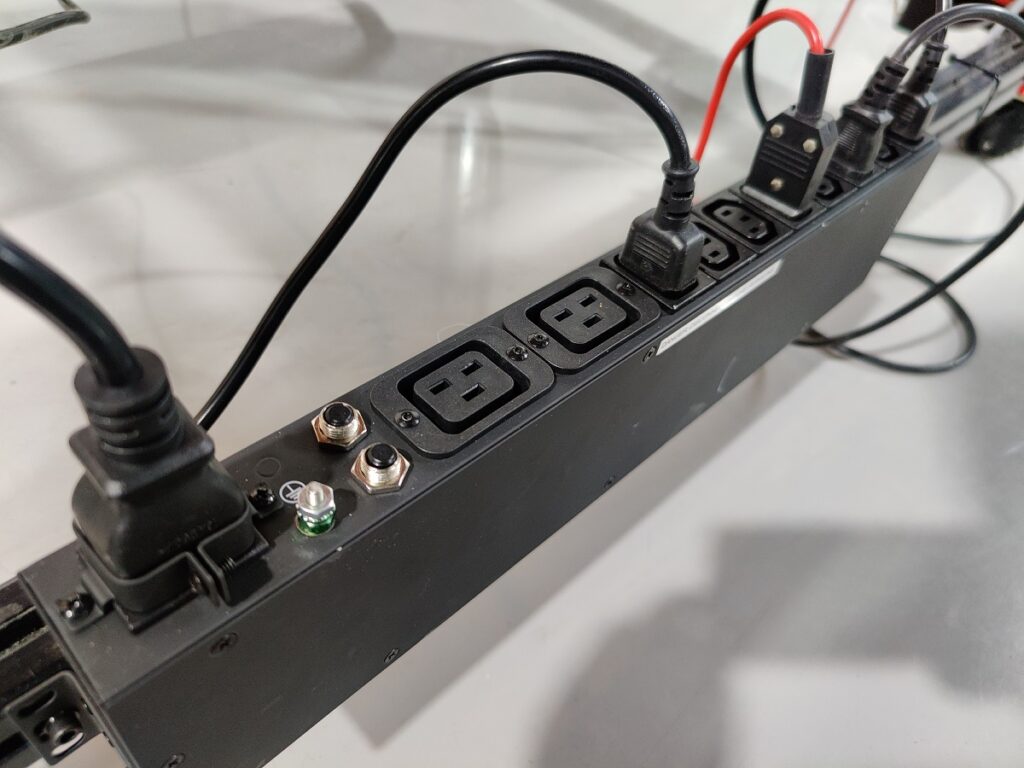

Power Distribution Unit (PDU)

PDU is included by default with the BIG-Meter and BIG-180X due to their high current drawing requirements. Since we have found it to be a very convenient cable management solution, it is now offered for all other models*. Replace 3 AC cables with only one cable connected to the wall.

* This solution does not support BIG-120X running on 110V, please contact the sales team for an alternative solution.

Filament

Easy to print: Simply adhere to Modix’s straightforward filament printing instructions

Material | Description |

PLA | “Eco-friendly, easy to print, ideal for various projects.” |

PETG | “Simple like PLA, strong like ABS, for versatile prints.” |

Intermediate: A bit of know-how and our Modix user guide is all you need, or simply opt for our “professional services”

Material | Description |

PP | “Fatigue-resistant and semi-flexible, for durable containers.” |

Nylon | “Strong, flexible, for parts needing toughness.” |

TPU | “Flexible and durable, perfect for bendable items.” |

MAS (Modix Advanced Support) | “Flawless support for complex prints, easy post-processing.” |

Advanced: Rely on Modix’s “professional services” for advanced assistance and in-depth expertise

Material | Description |

ABS | “Tough, heat-resistant, for functional mechanical parts.” |

ASA | “Strong like ABS with UV resistance, great for outdoors.” |

PC | “Ultra-tough and heat-resistant, for resilient parts.” |

HIPS | “Ideal support material, also for lightweight applications.” |

8KG Spools Mounting Shelf Add-on

A refreshed design of the spool mounting shelf will now enable mounting 8KG