Print-On-Demand is Coming to Furniture

The digital disruption that reshaped books, music and wall art is now changing furniture. Large pellet 3d printers are transforming how furniture are made.

- Large custom parts in hours, not weeks

- On-demand production, no inventory, no warehousing

- Lower landed costs, reduce import, shipping, and tariffs

- Sustainability that sells, locally recycled pellets

- AI-ready workflow, generate concepts and 3D models fast

Modix MAMA large pellet 3d printer brings affordability and industrial reliability to this new workflow: heavy-duty build, premium components, modular installation, and local support and training across North America and Europe.

Early-mover advantage is real! Act now. Contact Modix

Gallery

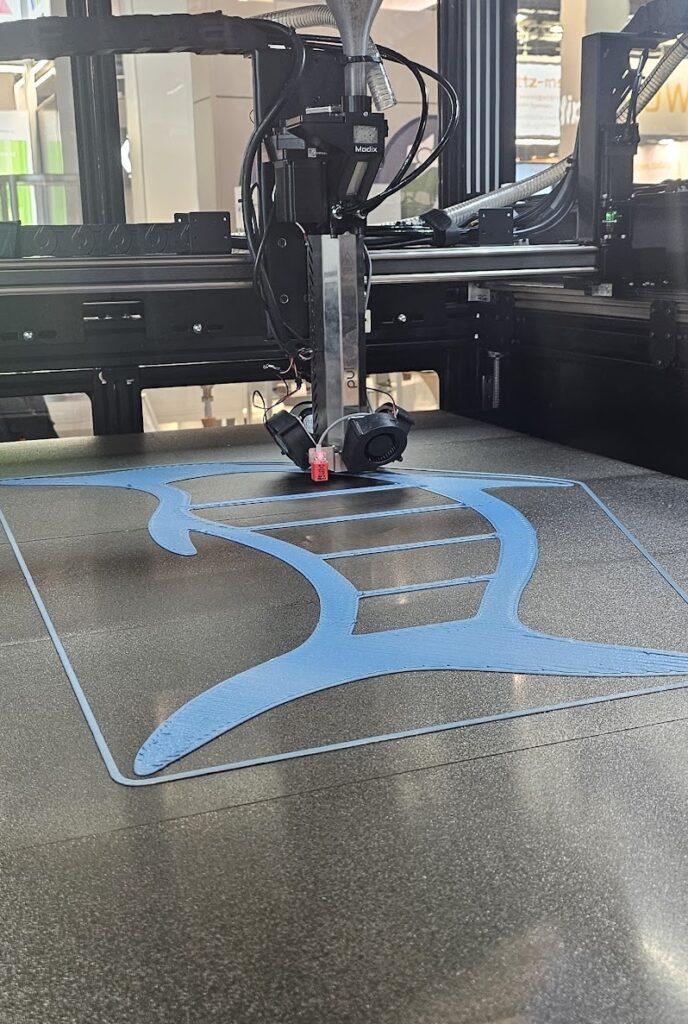

Right off the Printer Look and Feel

Gradient

Blend two pigments into a seamless gradient where one hue gradually transitions and dissolves into the other.

Plywood Like

Blend wood-based composite pellets with carefully dosed masterbatch additives to achieve a refined, plywood-inspired aesthetic.

Natural wood

Enjoy the natural wood texture – and even the smell- when printing with pellets made from wood waste blended into composite pellets.

How it Works

Pellets or Compounds

Low-cost plastic pellets, virgin or recycled. Compound is a blended with additives such as carbon fiber, minerals, or wood to improve strength, heat resistance, and surface finish.

Masterbatch

Add color and effects by blending masterbatch with the base pellets. Match any RAL or Pantone, and create custom looks like matte, speckle, stone, or glitter, depending on the application and brand style.

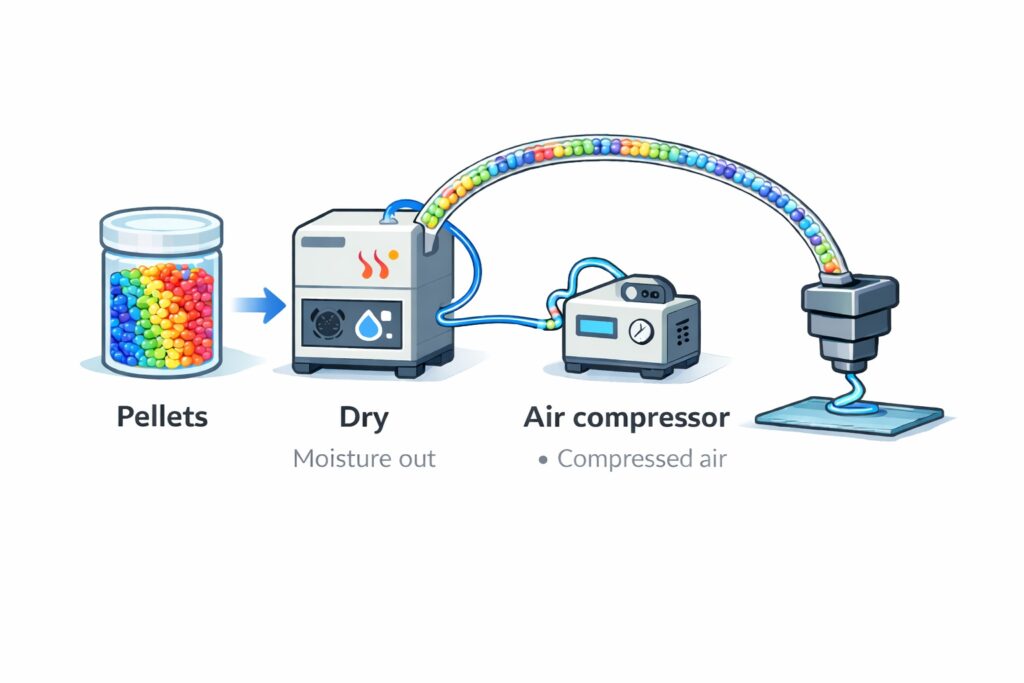

Drying & Feeding

Pellets must be dried before printing to prevent bubbles, weak bonding, and poor surface quality. Since the print head cannot pull the pellets, compressed air is used for feeding.

AI Design & 3D Printing - A New Process

AI Based Product Ideation

New AI tools can generate endless visual concepts – and turn them into 3D-ready models in minutes.

Low Cost & Fast Printing

Print with low-cost plastic pellets and produce ready-to-use parts in just a few hours.

Ready For Use

Use smart slicing and furniture-first design to get strong, functional parts straight off the printer.

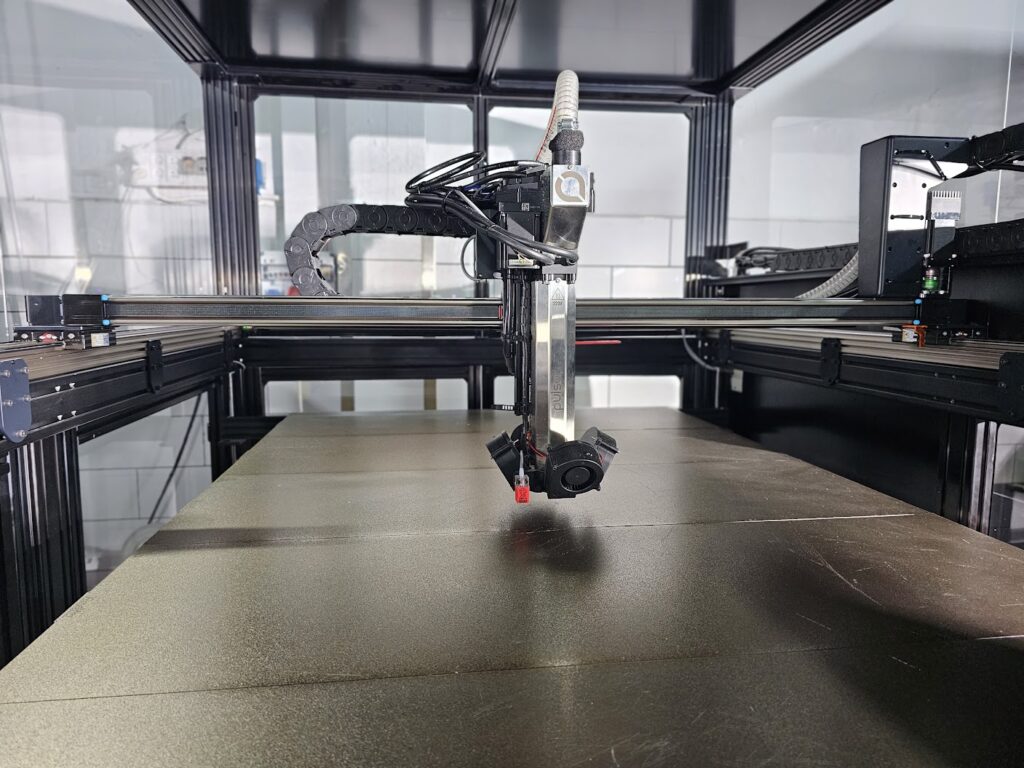

Modix Pellet 3D Printers

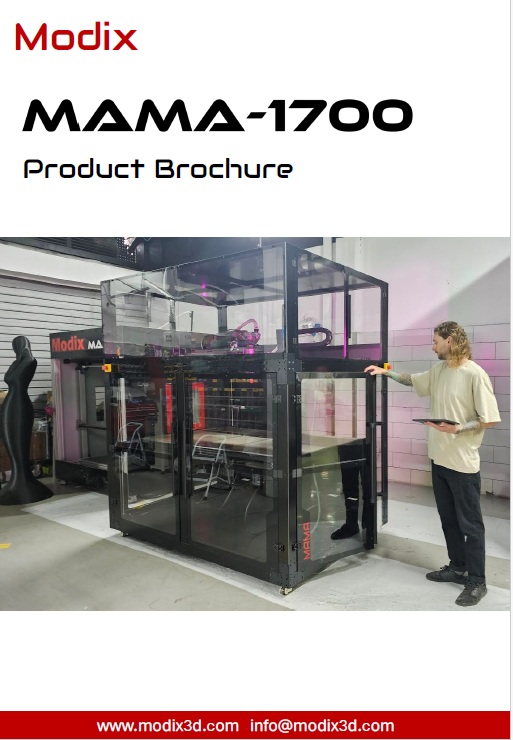

Modix MAMA 1700

MAMA 1700 is a Personal Furniture Factory. Print full-scale furniture parts with low-cost pellets and finish-ready surface textures, in a machine that fits workshops and can be installed through standard doors.

- Build volume: 1,700 x 1,000 x 1,000 mm (XYZ)

- Heated bed up to 120C for stable printing (5 independent zones)

- Ideal for: chairs, planters, table bases, decorative wall panels

- Configure it your way: pellet, filament, or dual filament (IDEX)

- Best for: fast iterations, local production, small-batch manufacturing

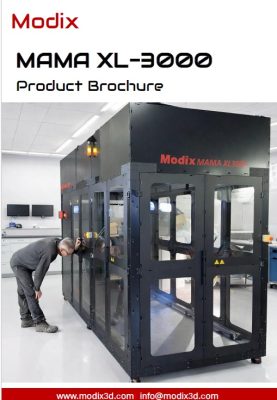

Modix MAMA XL-3000

MAMA XL-3000: Full-length printing for furniture production.

Go beyond “print-in-parts” by printing long, continuous furniture and large architectural elements in one run and batch production of small objects.

- Build volume: 3,000 x 1,000 x 1,000 mm (XYZ)

- Heated bed up to 120C for stable printing (9 independent zones)

- Ideal for: room dividers, architectural elements, large wall panels and batches of smaller items

- Configure it your way: pellet, filament, or dual filament (IDEX)

- Best for: larger batches, bigger parts, higher throughput workflows

Multiple add-ons

High Flow Filament Print Head

While pellets are the most cost-effective, filament delivers finer detail and sharper surface definition when needed.

Pellets Additives Mixer

Provides consistent color, allows matte finishes and generates repeatable production batches.

Pellets Dryer

Drying pellets reduces moisture-related defects, delivering cleaner surfaces and stronger and consistent results.

Get Started with Modix

Free consultation

A video call with a Modix application engineer to review your needs and recommend the right setup.

Modix Innovators Magazine

Discover real customer stories and applications, from aerospace to automotive and beyond.